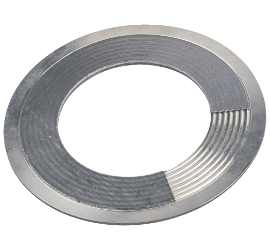

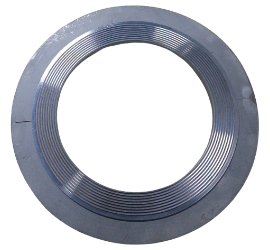

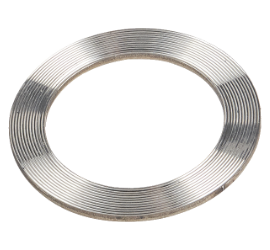

Kammprofile gaskets (also known as serrated or grooved gaskets) are manufactured from a solid metal core, with concentric grooves machined on the sealing surface. The grooves are usually filled with a soft sealing material such as graphite, PTFE, or mica to enhance sealing performance.

Performance

- Suitable for high temperature, high pressure, and highly corrosive media.

- The serrated groove design provides strong radial sealing action when compressed.

- Combines the strength of metal with the resilience of soft filler materials.

Advantages

- Excellent blowout resistance, capable of withstanding pressure fluctuations and mechanical shocks.

- Maintains stable sealing performance under extreme temperature and chemical conditions.

- Requires relatively lower bolt load to achieve effective sealing.

- Commonly used in petrochemical plants, nuclear power, pressure vessels, and heat exchangers.

Core Materials

Carbon Steel, ss304, ss304L, ss316(L), ss316Ti, ss321, s31803, s32726, Alloy 625, Alloy 825, Alloy C276, Monel 400, Titanium

Layer Materials

Graphite, Non-asbestos, Oxygen Inhibited Graphite, PTFE Tape

Specification

- Core Thickness

Standard thickness 3mm/4mm/5mm, others also available - Standard

ASME B16.21, DIN2691, EN1514-6, JIS B2404 and Customized - Country of Origin

People's Republic of China